What is a Water Backflow Preventer & Why Your Denver Home or Business Must Have One?

Clean, safe drinking water is something most Denver homeowners and business owners take for granted. But without a properly installed and maintained water backflow preventer, your plumbing system could allow contaminated water to flow backward into the public water supply — creating serious health risks and costly compliance issues.

In Denver, backflow prevention isn’t just recommended — it’s required for many residential, commercial, irrigation, and fire protection systems. Understanding how backflow occurs, which devices are required, and how testing and certification work can help protect your property, your customers, and the city’s water supply.

This guide explains what a backflow preventer is, why Denver properties must have one, and how professional installation and annual testing keep you compliant.

The United States relies on more than 259,000 water supply systems today. These critical systems use backflow prevention devices to protect drinking water that serves over 85% of Americans.

Clean water access depends entirely on these systems. Water backflow threatens your drinking water's safety. Contaminated water that flows backward into the main water supply can lead to illness, injury, and death.

A backflow preventer is a vital safety barrier that stops non-potable water from contaminating our clean water supply. Your Denver property's protection and health deserve the best safeguards.

This detailed backflow water prevention users guide will help you understand water backflow prevention, its mechanisms, and its legal requirements in most states. Let's dive into what you should know about maintaining a safe and compliant potable water supply in your Denver Home & Business.

WHAT IS A WATER BACKFLOW PREVENTER?

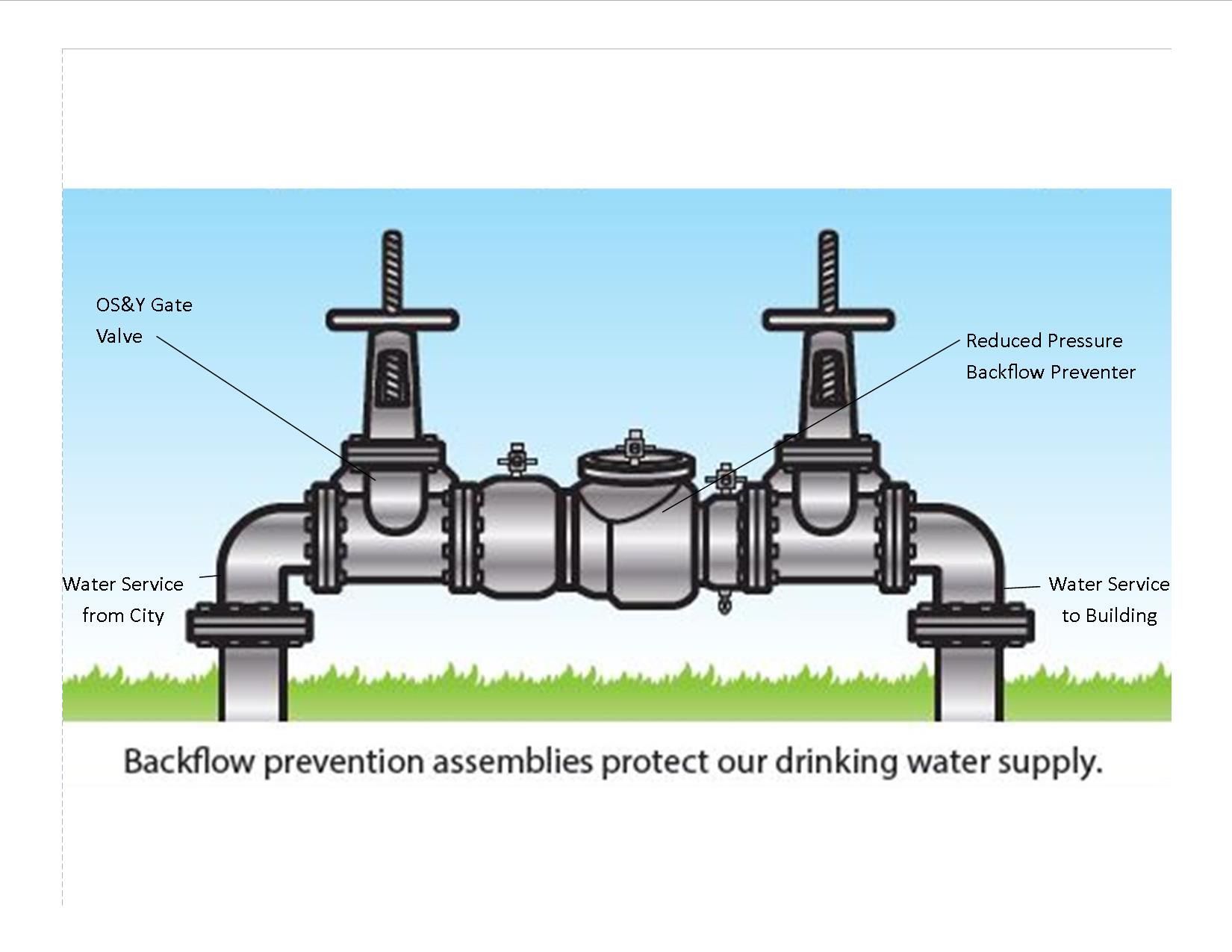

A backflow preventer is a mechanical device installed on a water line to stop water from flowing in the wrong direction. When pressure changes occur — such as a water main break or heavy demand on the system — contaminated water can be siphoned back into clean drinking water lines.

Backflow preventers automatically close when reverse pressure is detected, preventing pollutants like:

- Fertilizers and pesticides

- Industrial chemicals

- Bacteria and waste

- Stagnant irrigation water

These devices play a critical role in

cross-connection control, which is the prevention of unsafe connections between potable and non-potable water systems.

WHY BACKFLOW PREVENTION IS REQUIRED IN DENVER

Denver Water operates a strict Cross-Connection Control and Backflow Prevention Program to protect the municipal water supply. Properties with irrigation systems, fire sprinkler systems, commercial plumbing, or certain residential configurations are required to install USC-approved backflow assemblies.

Denver compliance requirements include:

- Installation of the correct backflow device based on system type

- Annual backflow testing by a certified backflow tester

- Submission of test results to Denver Water

- Repairs or replacement if the device fails inspection

Failure to comply can result in water service interruption, fines, or forced system upgrades.

The science behind backflow water is fascinating, and backflow prevention devices play a vital role in keeping our water safe. Water systems work on a basic principle - the right pressure ensures water flows in the intended direction.

Water Pressure Regulator

Pressure forces water through pipes, and altitude and gravity affect this process. Any unexpected pressure changes can create unsafe conditions. Two main types of water backflow exist:

- Backsiphonage: This happens at the time of water main breaks, maintenance, or high-demand activities like firefighting. It pulls water back into the system.

- Backpressure: This occurs when downstream pressure becomes higher than the main pressure. Pumps, elevation changes, or thermal expansion often cause this issue

A backflow prevention device, commonly known as a backflow preventer valve, is an essential component in plumbing systems designed to protect potable water supplies from contamination or pollution caused by backflow.

Backflow occurs when the normal flow of water is reversed, potentially allowing contaminants to enter the clean water supply.

This can happen due to changes in pressure within the water backflow system, such as during a sudden drop in water pressure or when a high-pressure hose is used.

A backflow preventer valve ensures that water only flows in one direction, safeguarding public health and maintaining the integrity of the water distribution network.

The backflow prevention device operates through check valves and pressure relief mechanisms that prevent the contaminated water from flowing back into the clean water supply.

These valves are typically installed at key points in the plumbing system, such as where the water supply enters a building or at critical cross-connection points. Several backflow preventer valves include reduced pressure zone (RPZ) assemblies, double-check valve assemblies, and pressure vacuum breakers.

Each type serves specific applications and offers varying protection against backflow incidents. Regular backflow prevention device inspection, maintenance, and testing is crucial to ensure its proper functioning.

Local Denver, CO, regulations often mandate annual inspections by certified professionals to verify that the valves are operating correctly and identify potential issues.

This preventive backflow measure helps avoid costly repairs and ensures the water supply remains safe and uncontaminated. In addition, property owners should be educated about the importance of backflow prevention and the role of these devices in protecting public health.

In summary, a backflow prevention device, or backflow preventer valve, plays a vital role in maintaining the safety and quality of water supplies.

By preventing the reverse flow of contaminated water into potable water systems, these valves help to avert health hazards and ensure compliance with regulatory standards. Regular backflow inspection and maintenance of these devices are essential to their effectiveness, making them indispensable to modern plumbing systems. Call

Drain Brain LLC 720-322-4845

A Reduced Pressure Backflow Preventer (RPBP) is a vital component in plumbing systems that protect potable water supplies from contamination. This sophisticated device ensures that any reverse flow of water, which could potentially carry harmful contaminants, is effectively prevented.

The RPBP operates by maintaining a valve mechanism that reduces the pressure in the pipeline, thereby preventing backflow.

It is particularly crucial in environments where the risk of backflow is high, such as in commercial and industrial settings. The backflow-reduced pressure mechanism within the valve is engineered to detect and respond to changes in water pressure, ensuring consistent protection against contamination.

A Reduced Pressure Backflow Preventer's installation and regular maintenance are essential for its optimal performance. Plumbers and maintenance personnel must ensure that the valve is functioning correctly and that there are no signs of wear or damage.

Regular backflow-reduced pressure system testing is also necessary to comply with health and safety regulations. Moreover, understanding the operation of this valve helps troubleshoot any potential issues that may arise, thereby preventing costly water system failures and ensuring a continuous supply of safe drinking water.

The Reduced Pressure Backflow Preventer is indispensable to modern plumbing infrastructure. Its role in maintaining water quality by preventing backflow cannot be overstated.

By incorporating a reliable backflow valve system that reduces pressure, these water backflow devices offer robust protection against contamination.

Upholding stringent maintenance and testing protocols ensures that the backflow-reduced pressure preventer performs its function efficiently, safeguarding homeowners and public health and maintaining the integrity of potable water systems.

A Reduced Pressure Principal Backflow Preventer an essential device in safeguarding potable water supplies against contamination due to backflow. This sophisticated assembly is designed to maintain a reduced pressure zone between two check valves, ensuring any backflow is expelled from the system rather than re-entering the clean water supply.

The core functionality relies on the backflow reduced pressure principle, which acts as a critical barrier against pollutants and contaminants that could otherwise compromise the safety and quality of drinking water. The assembly comprises several key components, including two independently acting check valves and a hydraulically operating, mechanically independent relief valve.

These Reduced Pressure Principal Backflow Preventer elements work together to create a reliable backflow prevention mechanism. When the upstream pressure drops below downstream pressure, the relief valve opens, discharging water to maintain the reduced pressure zone and protect against potential backflow.

This Reduced Pressure Principal Backflow Preventer assembly process ensures that any negative pressure or siphonage conditions are effectively managed, preventing contaminated water from flowing backward into the clean supply. Regular maintenance and testing of the backflow reduced pressure assembly are crucial to ensure its optimal performance.

Drain Brain LLC must inspect the valve components for wear and tear, ensuring that all parts function correctly to prevent malfunctions. Proper installation and periodic checks are necessary to comply with local regulations and standards, which mandate stringent measures to protect public health and safety.

By adding a Reduced Pressure Principal Backflow Preventer, municipalities, industries, and residential properties can provide an additional layer of defense against water supply contamination, thereby upholding the integrity of potable water systems.

A sewer backflow preventer valve is an essential backflow prevention device designed to protect residential properties from the infiltration of wastewater and sewage. Installed within the sewer line, this device plays a critical role in preventing contaminated water from flowing back into homes, which can cause significant health hazards and property damage.

The importance of a sewer backflow preventer valve cannot be overstated, especially in areas prone to heavy rainfall or flooding, where the risk of sewer line backups is significantly higher.

A backflow prevention device functions by allowing water to flow in only one direction—out of the residential property and into the municipal sewer system. In the event that pressure within the sewer line increases, which could cause a reverse flow, the valve automatically closes, thereby preventing contaminated water from entering the residential plumbing system.

This mechanism ensures that households remain safeguarded against potential exposure to hazardous materials that could compromise both health and hygiene. For residential properties, installing a sewer backflow preventer valve is not just a precautionary measure but a necessary investment in long-term safety and maintenance.

Residential properties with basements, lower levels, or those located in flood-prone areas are particularly vulnerable to sewer backups. In such cases, the installation of a reliable backflow prevention device is indispensable. Regular maintenance and inspection of the sewer line and the backflow prevention device are also crucial to ensure their optimal functioning.

It is advisable to engage Drain Brain LLC professional sewer repair services for installation and maintenance to ensure that the device complies with local building codes and industry standards. In summary, a sewer backflow preventer valve is a major and vital component of any residential plumbing system, providing robust protection against the detrimental effects of sewer line backups.

As a highly effective backflow prevention device, it ensures that contaminated water does not re-enter residential properties, thereby preserving the integrity of the home’s plumbing system and safeguarding the potable water and the health of its occupants. Homeowners should prioritize the installation and regular upkeep of water backflow preventer devices to maintain a safe and sanitary living environment.

A sewer backflow preventer valve is an essential backflow prevention device designed to protect residential properties from the infiltration of wastewater and sewage. Installed within the sewer line, this device plays a critical role in preventing contaminated water from flowing back into homes, which can cause significant health hazards and property damage.

The importance of a sewer backflow preventer valve cannot be overstated, especially in areas prone to heavy rainfall or flooding, where the risk of sewer line backups is significantly higher. A backflow prevention device functions by allowing water to flow in only one direction-out of the residential property and into the municipal sewer system. If pressure within the sewer line increases, which could cause a reverse flow, the valve automatically closes, thereby preventing contaminated water from entering the residential plumbing system.

This mechanism ensures that households remain safeguarded against potential exposure to hazardous materials that could compromise both health and hygiene. For residential properties, installing a sewer backflow preventer valve is not just a precautionary measure but a necessary investment in long-term safety and maintenance.

Properties with basements, lower levels, or those located in flood-prone areas are particularly vulnerable to sewer backups. In such cases, the installation of a reliable backflow prevention device is indispensable. Regular maintenance and inspection of the sewer line and the backflow prevention device are also crucial to ensure their optimal functioning.

It is advisable to engage professional services for installation and maintenance to ensure that the device complies with local building codes and industry standards. In summary, a sewer backflow preventer valve is a vital component of any residential plumbing system, providing robust protection against the detrimental effects of sewer line backups.

As a highly effective backflow prevention device, it ensures that contaminated water does not re-enter residential properties, thereby preserving the integrity of the home’s plumbing system and safeguarding the health of its occupants. Homeowners should prioritize the installation and regular upkeep of these devices to maintain a safe and sanitary living environment. Call

Drain Brain LLC at 720-322-4845 for an inspection or maintenance of your Backflow Preventer.

A sewer water backflow preventer is an essential device for residential and commercial plumbing systems. The water backflow preventer valve is specifically designed to prevent the reverse flow of contaminated sewer water into clean water supplies and living spaces.

By installing a sewer water backflow preventer, Denver, CO, home & business owners can safeguard their premises from potential health hazards, property damage, and costly repairs that could arise from sewer water backflow incidents. The device operates by allowing wastewater to flow in only one direction—out of the building—thereby preventing any backflow during instances of heavy rainfall, flooding, or system blockages.

The importance of a sewer water backflow preventer cannot be overstated. The device plays a crucial role in maintaining the integrity and hygiene of plumbing systems. An effective backflow preventer valve ensures that the risk of water contamination is minimized, providing peace of mind to property owners.

Regular sewer line inspection and maintenance of the sewer water backflow preventer are also vital to ensure the backflow valve is properly functioning over time. By neglecting the sewer line inspection and maintenance could lead to backflow valve failure, which can result in severe consequences, including exposure to harmful pathogens and extensive damage to home and business property infrastructure.

Investing in a reliable sewer water backflow preventer is a wise decision for anyone looking to protect their Denver home and business property and health. This water backflow prevention device serves as a critical barrier against the dangers posed by sewer water backflow, ensuring that wastewater does not re-enter clean water lines or living areas.

By understanding the significance of this backflow valve and committing to its regular upkeep, Denver home and business property owners can effectively mitigate the risks associated with sewage systems, thereby maintaining a safe and sanitary environment.

A Sewer Backflow Preventer Valve is an essential component in modern plumbing systems, designed to safeguard Denver homes from the damaging effects of sewer backups. This device, commonly known as a Sewer water backflow preventer, is strategically installed in the sewer line to prevent wastewater from flowing back into a home or building.

The valve operates by allowing sewage to flow in only one direction—outward towards the main sewer line—thus ensuring that any reversal in flow due to blockages or heavy rainfall does not lead to contamination or flooding inside the premises. The installation of a Sewer Backflow Preventer Valve is particularly crucial in areas prone to heavy rainfall or where the municipal sewer system is aging and prone to blockages.

By incorporating this device, property owners can mitigate the risks associated with sewer backups, which can cause extensive property damage, health hazards, and financial burdens. The valve itself is engineered to be durable and reliable, often made from corrosion-resistant materials to ensure long-term functionality and minimal maintenance.

For optimal performance, it is important that the Sewer water backflow preventer is installed by a qualified plumber or sewer line professional who can assess the specific needs of the home or building property and ensure proper backflow valve placement and installation.

Regular sewer inspections and maintenance of the backflow valve are also recommended to ensure its continued effectiveness. By investing in a Sewer Backflow Preventer Valve, property owners are taking proactive steps to protect their investments and maintain a safe living environment. This device represents a small but significant measure in the overall strategy of modern plumbing solutions aimed at enhancing public health and safety.

A backflow prevention device is one of the most critical and essential components in any plumbing system, designed to keep residential & commercial potable water supplies safe from contamination or pollution due to backflow. Backflow occurs only when the direction of water flow reverses, which can happen due to various reasons such as changes in pressure.

The unintentional reverse flow can introduce contaminants into clean water sources, posing significant health risks. The backflow prevention device ensures that water flows in only one direction, thereby safeguarding the integrity of the water supply. The assembly of a backflow prevention device involves various critical parts, each playing a vital role in its operation.

Common parts in a typical backflow assembly include check valves, which prevent reverse flow; relief valves, which release pressure and avoid damage to the system; and shut-off valves, which allow for device isolation for maintenance or inspection. The backflow assembly of these parts must be meticulously carried out to ensure that the device functions correctly and provides reliable protection.

Proper installation and maintenance of a backflow prevention device are crucial for its effectiveness. Following manufacturer guidelines and local plumbing codes is essential to ensure compliance and functionality during the assembly process. Regular inspections and testing of the device are also necessary to identify and rectify any issues that may compromise its performance.

Professional Denver Plumbers like Drain Brain LLC

Equipped with the right tools and sewer and water line knowledge, are best suited to handle the installation and maintenance tasks associated with backflow assembly. In addition to safeguarding public health, a well-maintained backflow prevention device can help avoid costly repairs and potential legal liabilities. Neglecting regular maintenance can lead to malfunctioning parts within the assembly, causing failures that could result in contamination incidents.

Therefore, property owners and facility managers should prioritize routine checks and prompt servicing of their backflow prevention devices. Overall, understanding the importance of each part within a backflow assembly and ensuring its proper installation and maintenance of the backflow preventer is essential for maintaining a safe water supply.

By investing in high-quality backflow prevention devices and adhering to recommended practices for their assembly and upkeep, individuals and organizations can effectively mitigate the risks associated with water contamination due to backflow.

Backflow prevention is critical in maintaining water supply systems' safety and integrity. A backflow prevention device is designed to prevent the reverse flow of water, which can lead to contamination of potable water supplies. This device only ensures that water flows in one direction, preventing any potential hazards from back siphonage or back pressure.

The importance of having a reliable backflow prevention device cannot be overstated, as it safeguards against pollutants and contaminants that could otherwise compromise public health. Installing a backflow prevention device involves a precise and careful assembly process. The assembly of these devices typically includes components such as check valves, air gaps, and pressure vacuum breakers.

Each element is crucial in ensuring the device functions correctly and efficiently. Proper assembly is critical to the device's effectiveness. It must be carried out by qualified professionals who understand the intricacies involved.

Regular backflow preventer maintenance and inspection are also essential to ensure that the backflow device continues to perform optimally over time. When considering backflow prevention measures, it is necessary to factor in the cost. The cost of a backflow prevention device depends largely on the type and complexity of the backflow prevention system required. While an initial investment may exist, the long-term benefits outweigh the costs. Preventing contamination incidents can save significant money that would otherwise be spent on rectifying health hazards and addressing water quality issues.

Furthermore, compliance with regulatory standards often necessitates installing these devices, making them indispensable to water management systems. The significance of backflow prevention cannot be understated in ensuring the safety and purity of water supplies. A backflow prevention device is essential in preventing contamination and safeguarding public health.

Proper assembly and regular maintenance are key to effectively operating these devices. Though their installation has an associated cost, the investment pays off by avoiding potential health risks and complying with regulatory requirements. Therefore, prioritizing backflow prevention is a wise and necessary decision for any organization responsible for maintaining water quality.

Backflow preventer testing is a critical procedure ensuring potable water systems' integrity and safety. The cost associated with backflow preventer testing will vary depending on a few factors, including the type and size of the backflow preventer, location, and system complexity.

Typically, backflow preventer testing costs between $50 and $150 per device. However, costs can escalate if repairs or replacements are needed following the initial test. Regular backflow preventer testing helps to avert potential contamination and ensures compliance with local water authority regulations. Neglecting this essential backflow preventer testing inspection and maintenance can lead to severe consequences, including hefty fines and health hazards.

Therefore, home and business property owners must factor in periodic backflow preventer testing costs as part of their routine maintenance budget. Professional service providers usually offer comprehensive packages that include both testing and certification. You should always seek quotes from multiple certified backflow water prevention technicians to ensure the cost aligns with industry standards while not compromising quality.

Furthermore, establishing a long-term relationship with a reliable service provider can sometimes lead to discounted rates for backflow preventer testing, thereby reducing overall expenses. Drain Brain LLC is an affordable backflow prevention expert.

While the cost of backflow preventer testing may seem like an additional expense, it is an essential investment in safeguarding public health and maintaining regulatory compliance. Property owners should prioritize regular testing and budget accordingly to avoid more significant costs associated with drinking water contamination or system failure in the future.

When considering the installation of a backflow preventer device, it is essential to understand the associated cost factors to make an informed decision. The cost of a backflow preventer device can vary significantly based on a few factors, including the type of backflow device, its size, and the complexity of the installation process.

Typically, the price range for these backflow preventer devices can start as low as $100 for basic models and can go upwards of $1,000 for more advanced or more extensive backflow prevention systems. This price often reflects the backflow preventer device, and any additional accessories or fittings required for proper installation. Another critical aspect that impacts the overall cost is the labor involved in installing the backflow preventer device.

Professional backflow preventer device installation is highly recommended to ensure the device functions correctly and complies with local plumbing codes. Labor costs can add anywhere from $200 to $500 or more to the total price, depending on the job's complexity and regional labor rates.

Additionally, there may be ongoing maintenance costs, as regular inspections and testing are necessary to ensure the backflow preventer device remains in good working order. Moreover, it is essential to consider any potential costs associated with repairs or replacements over time. While high-quality backflow preventer devices are built to last, they can still be subject to wear and tear or damage under certain conditions.

Ensuring that you budget for these contingencies can help avoid unexpected expenses in the future. Overall, while a backflow preventer device's initial cost and price might seem significant, investing in one is crucial for protecting your water supply from contamination, making it a valuable and necessary expense. Call Drain Brain LLC, for a free estimate and inspection of your backflow preventer device, at 720-322-4845

When considering the installation of a backflow preventer device, it is essential to understand the associated cost factors to make a wise, informed decision. The cost of a backflow preventer device will vary significantly based on several factors, including the type of backflow device, its size, and the complexity of the installation process. Typically, the price range for these devices can start as low as $100 for basic models and can go upwards of $1,000 for more advanced or more extensive systems.

This price often reflects the backflow preventer device and any additional accessories or fittings required for proper installation. Another critical aspect that impacts the overall cost is the labor involved in installing the backflow preventer device. Professional backflow preventer installation is highly recommended to ensure the device functions correctly and complies with local plumbing codes. Backflow prevention devices' labor costs can add anywhere from $200 to $500 or more to the total price, depending on the job's complexity and regional labor rates.

Additionally, there may be ongoing maintenance costs, as regular inspections and testing are necessary to ensure the backflow preventer device remains in good working order. Moreover, it is essential to consider any potential costs associated with repairs or replacements over time. While high-quality backflow preventer devices are built to last, they can still be subject to wear and tear or damage under certain conditions.

Ensuring that you budget for these contingencies can help avoid unexpected expenses in the future. While a backflow preventer device's initial cost and price might seem significant, investing in a high-quality one is crucial for protecting your water supply from contamination, making it a valuable and necessary expense.

When it comes to maintaining the integrity of your sprinkler system, ensuring the proper functioning of the backflow preventer device is crucial. A backflow preventer device is essential for preventing contaminants from entering the clean water supply through the sprinkler system. However, like any mechanical component, it may eventually need to be replaced.

The replacement cost for a backflow preventer device can vary significantly based on several factors, including the type and size of the device, labor charges, and regional pricing differences. On average, the cost to replace a backflow preventer device range from $150 to $1,000. This price range accounts for the new device and associated labor costs.

The price might be on the lower end for smaller residential systems, while larger commercial systems often incur higher costs. It's important to consider that if additional plumbing work or modifications are necessary during the replacement process, this can further influence the overall cost. When seeking to replace a backflow preventer device, obtaining multiple quotes from licensed professionals is advisable.

This will give you a clearer picture of the expected price and help you find the best deal without compromising quality. Additionally, regular maintenance and inspections can help extend the lifespan of your backflow preventer device, potentially reducing long-term replacement costs. Investing in timely replacements and ensuring compliance with local regulations are essential to maintaining a safe and efficient sprinkler system.

In summary, while the initial cost to replace a backflow preventer device might seem substantial, it is a necessary expense to ensure water safety and system reliability. By understanding the factors influencing price and seeking professional guidance, you can manage these costs effectively while safeguarding your water supply.

Prevents Water Backflows Cross-Connection Hazards

A cross-connection happens at any point where drinking water connects to non-potable sources. These connections create substantial risks to our water supply. Common cross-connections include, Swimming pools, irrigation systems, and fountains can let contaminated water mix with clean water. A simple garden hose left in a bucket of cleaning solution can create a dangerous cross-connection.

Backflow Water Contamination Risks Explained

Pressure fluctuations make contamination risks more serious. Data shows that water distribution systems experience about 25-30 breaks per 100 miles of piping each year. These breaks create perfect conditions to contaminate water.

Backflow incidents can introduce these contaminants into drinking water:

- Chemical pollutants from industrial processes

- Biological contaminants from irrigation systems

- Stagnant water from fire sprinkler systems

Contamination severity changes based on the source. Some incidents affect only water's taste and smell, while others pose health risks. This shows why proper backflow prevention devices matter in every water system.

You need to think over multiple factors to pick the right backflow prevention device. Your property's unique characteristics and usage patterns will shape these requirements.

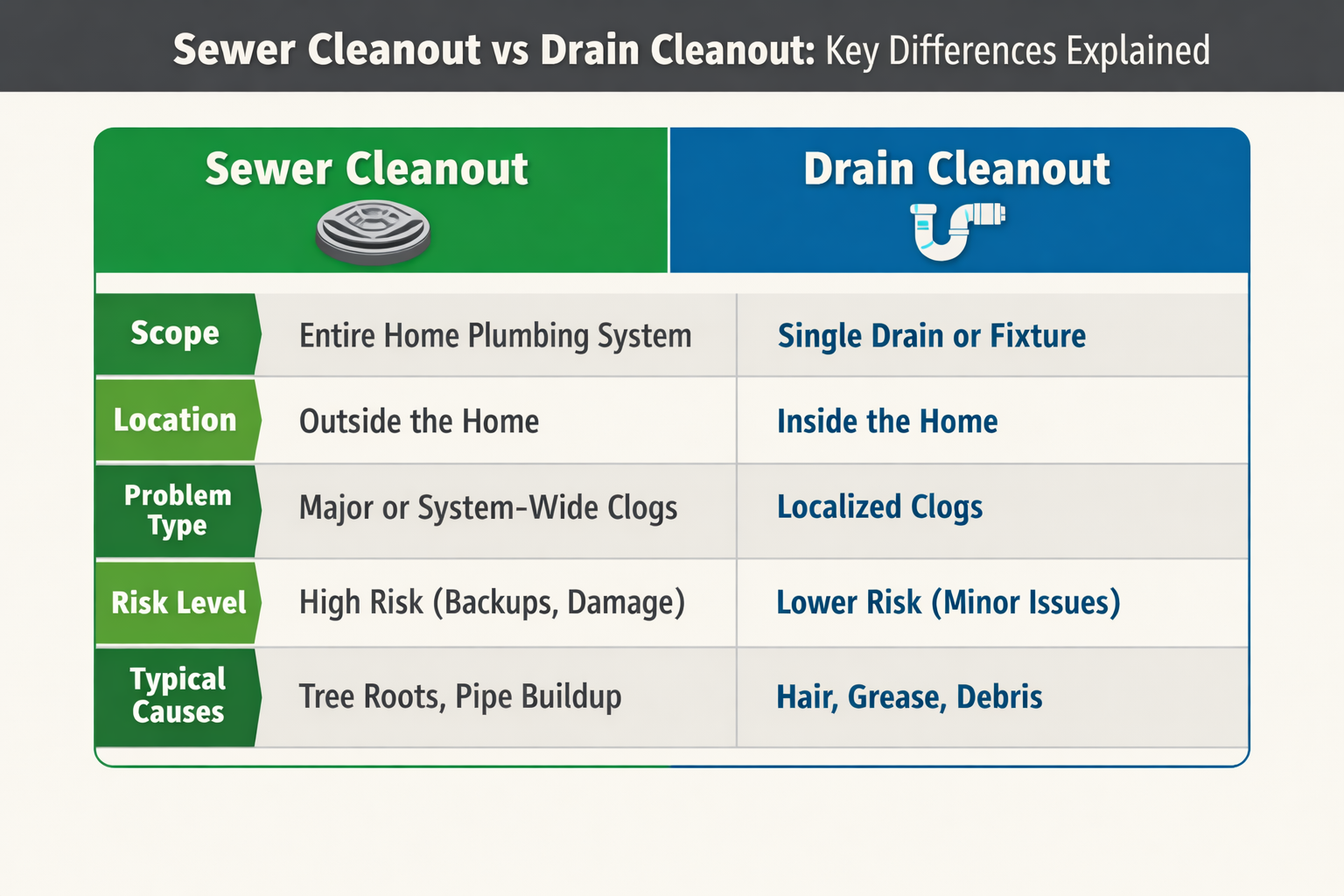

TYPES OF BACKFLOW PREVENTERS & WHEN THEY’RE USED

Not all backflow preventers are the same. The type required depends on how your property uses water and the level of contamination risk.

Common backflow preventer types include:

Reduced Pressure Zone (RPZ) Assemblies

Used for high-hazard applications such as commercial buildings, medical facilities, and industrial sites.

Double Check Valve Assemblies (DCVA)

Common for fire sprinkler systems and low-to-moderate hazard applications.

Pressure Vacuum Breakers (PVB)

Often installed on irrigation systems to prevent fertilizer and pesticide contamination.

Atmospheric Vacuum Breakers (AVB)

Typically used for residential irrigation and hose bib protection.

Choosing the wrong device can lead to failed inspections and non-compliance, which is why professional evaluation is essential.

Keywords added:

RPZ backflow preventer Denver, irrigation backflow preventer, fire sprinkler backflow, backflow device types.

BACKFLOW TESTING & INSPECTION: WHAT TO EXPECT

In Denver, most backflow devices must be tested annually by a licensed professional. During a backflow inspection, a certified tester will:

- Verify proper installation and orientation

- Test internal check valves and relief components

- Measure pressure differentials

- Identify leaks or mechanical failures

- Submit certification results to Denver Water

If your system fails, repairs or replacement must be completed before re-testing.

Typical backflow testing costs depend on:

- Device type and size

- Accessibility

- Commercial vs residential systems

Annual testing ensures your system remains safe, functional, and compliant.

REAL-WORLD BACKFLOW RISKS FOR HOMES & BUSINESSES

Backflow incidents aren’t rare — and the consequences can be serious.

Examples include:

- Irrigation systems pulling pesticide-laden water into drinking lines

- Fire sprinkler systems containing stagnant water entering potable plumbing

- Restaurants and medical facilities creating cross-connections with chemicals

Without proper prevention, a single pressure change can contaminate an entire water system. Backflow preventers protect not only your property but your neighbors and community as well.

INSTALLATION & MAINTENANCE BEST PRACTICES

Professional backflow installation ensures:

- Correct device selection

- Code-compliant placement

- Freeze protection for Denver winters

- Long-term reliability

Maintenance tips:

- Schedule annual testing early to avoid compliance deadlines

- Protect outdoor devices from freezing temperatures

- Address small leaks immediately

- Keep certification records accessible

Proper maintenance reduces costly emergency repairs and failed inspections.

Backflow Preventer Device Assessment of Property Needs

The evaluation starts with your home and business property type and water usage patterns. Simple backflow prevention solutions work well for residential properties. Commercial facilities need more reliable systems. Properties with these features need special attention:

- Swimming pools

- Irrigation systems

- Fire sprinkler systems

- Chemical processing equipment

These features shape your choice of backflow prevention device. To cite an instance, homes get water from underground main supplies, and pressure changes can trigger reverse flow that needs prevention measures.

Backflow Risk Level Evaluation

Your hazard level determines which backflow preventer you'll need. Here's a full picture of risk assessment:

Hazard Level Examples Recommended Device

High Hospitals, medical facilities, sewage plants https://backflowprevention.com.au/backflow-prevention-requirements/ Food preparation or food storage tanks, vats and vessels

Medium Irrigation systems, fire services https://backflowprevention.com.au/backflow-prevention-requirements

Low Standard residential properties https://backflowprevention.com.au/backflow-prevention-requirements/

Local regulations also set specific requirements based on your home or business property's risk category. The presence of hazardous fixtures or chemicals that could contaminate the water supply needs attention.

Residential Backflow Preventer

The right size backflow preventer is vital for optimal performance. Most homes need devices that support 4-80 GPM (gallons per minute). Commercial properties usually need support for 100 GPM or more.

Your device size depends on:

- Flow rate requirements

- Available pressure

- Pipe size compatibility

- Installation space constraints

To name just one example, small office buildings and churches typically use 2-inch to 4-inch backflow preventers. Large buildings usually need 8-inch or larger diameter devices. Device size substantially affects its performance and system efficiency.

The chosen device must meet all local plumbing codes and requirements. Good relationships with local plumbing inspectors and water authorities help ensure compliance and avoid getting pricey mistakes.

Note that adding the known maximum demand for all fixtures gives you the total theoretical demand for a water supply system. Working with certified professionals helps you get an accurate assessment of your needs and find the most suitable backflow prevention solution.

Backflow Prevention Device Smart Technology Integration

Backflow Prevention Device Smart Technology Integration

Technology has changed the way we monitor and maintain backflow prevention devices. The Internet of Things (IoT) has brought sophisticated monitoring systems that give us better control and safety than ever before.

Modern Water Backflow Preventer Monitoring Systems

Backflow prevention monitoring has seen remarkable progress. Modern systems feature wireless monitors that detect relief valve discharge and alert facility managers about backflow conditions right away. These advanced sensors take pressure readings four times per second, running non-stop throughout the day.

The monitoring capabilities include:

- Up-to-the-minute pressure readings sent directly to building management systems

- Instant alerts for relief valve water discharge

- Automated flood protection mechanisms

- Performance tracking of multiple devices

Remote Backflow Water Prevention Testing Capabilities

Remote access has revolutionized backflow preventer management. A single online dashboard now let’s facility managers watch multiple devices. These systems give users the ability to: Feature Benefit Remote Control Perform valve adjustments from anywhere.

Up-to-the-minute Alerts: Receive notifications via email or text. Automated Testing: Schedule and conduct routine checks remotely. Emergency Response: Shut off water supply remotely during incidents.

Three test points each have pressure sensors, enabling continuous monitoring across multiple zones. These sensors detect pressure changes of just 1 gallon of backflow, providing exceptional accuracy.

Backflow Prevention Digital Maintenance Tracking

Building management systems have grown more sophisticated in tracking maintenance needs. Maintenance personnel can check performance data and trends from any location through secure web-based portals.

The technology provides predictive maintenance capabilities:

- Early warning signs of issues without visual inspection

- Pattern recognition for device performance

- Automated scheduling of maintenance activities

- Historical data analysis for preventive care

Digital solutions have changed traditional maintenance methods completely. Performance monitoring systems now track devices around the clock, unlike the old way of testing only once a year. The collected data helps identify patterns that show how devices perform over time.

Building management systems (BMS) integration creates an all-encompassing approach to water safety. These systems can communicate directly with third-party BMS via standard MODBUS protocols once activated via sensor connection kits. Facility managers can now act before problems occur, rather than just react to backflow events.

Emergency Water Backflow Preventer Response and Protection

Water safety never takes a break when it comes to protecting our supply. Quick action during backflow incidents can make the difference between a small hiccup and a major disaster.

Handling backflow incidents

We need to spot the signs of potential backflow incidents early. Our experience shows these warning signs point to trouble:

- Discolored or unusual-looking water

- Taste and odor irregularities (chemical, medicinal, or salty)

- Low or no chlorine residual in the distribution system

- Unexpected pressure changes

Time is crucial once we spot a backflow incident. Research shows that certified specialists must reach the site within an hour for systems serving 3,000 or more connections. Our team starts containment immediately to prevent contamination from spreading. Don't wait, call Drain Brain LLC 720-322-4845 at the first sight of water contamination. Click here to find your home or business water main shutoff valve

Emergency Water Shutdown Procedures

We've built a detailed emergency response plan from years of hands-on experience. Here's our tested approach:

Response Phase Action Items

Immediate Response: Isolate the affected area, shut off the water supply

Assessment: Identify contamination source, assess risk level

Communicatio:n Notify authorities, issue public health notices

Remediatio:n Implement flushing procedures, restore safe conditions

We must decide whether to issue a "do not use" or "boil water" notice. Of course, suspected chemical contamination requires a "do not use" notice until we get official clearance.

Click here to find your home or business water main shutoff valve

Water Contamination Prevention Protocols

Prevention remains our best defense against water backflow incidents. In spite of that, many incidents go unreported because:

- They don't last long

- Customers don't know about reporting requirements

- People aren't sure who to contact

Our backflow prevention strategy relies on detailed records of:

- Cross-connection locations

- Valve positions

- Access points

- Potential health hazards

Unidirectional flushing is effective at preventing contamination. This method tackles pipe sections one at a time, typically moving from the source to the periphery. Our monitoring program includes regular baseline water-quality testing. We keep watch to make sure backflow prevention devices work right and spot new hazards early. Our team gets extensive training to recognize and respond to backflow incidents.

Strict cleanup protocols guide us when water contamination happens. We flush the system to remove contaminants and disinfect it to cut down waterborne disease risks. Water quality samples confirm our system meets drinking water standards afterward.

Regular surveillance keeps our prevention program strong. We spot and fix potential problems through routine inspections before they turn serious. Every incident gets documented with details about:

- The type of cross-connection involved

- Contaminant characteristics

- Affected area boundaries

- Cleanup methods used

- Population impact data

These strict protocols and constant vigilance protect our water supply from contamination. If something goes wrong, our emergency response procedures help us act quickly and effectively to keep the public safe.

Legal and Insurance Implications of a Water Backflow Preventer Not Working Properly?

Property owners and businesses need to understand the legal scene of water backflow prevention. Many cases show how ignoring these requirements leads to serious problems.

Liability Considerations

Safe water systems need more than just installing backflow prevention devices. Property owners carry much liability to ensure these systems work right. Without doubt, you could be liable if an unprotected or poorly protected cross-connection causes a backflow incident. The costs might include:

- Medical expenses

- Property damage

- Loss of income

- Court costs

- Repair expenses

Water damage ranks third among the most expensive insurance claims, right after fire and liability lawsuits. This might sound scary, but knowing your duties helps protect your interests and public health.

Insurance Requirements

Your insurance coverage for backflow prevention needs close attention. Standard homeowners insurance doesn't usually cover water backup damage. You should think over these vital coverage aspects:

Insurance Coverage Type Requirements Purpose

General Liability USD 1 million per occurrence Covers bodily injury and property damage.

Water Backup Coverage Optional Endorsement Protects against sewage backup damages.

Errors & Omissions Required for testers covers testing and certification mistakes.

Water backup coverage proves valuable when problems happen, even though it's optional sometimes. This coverage helps pay for:

- Repairs to damaged personal property

- Structural repairs (floors, walls)

- Clean-up costs

Water Backflow Preventer Compliance Documentation

Good documentation serves as your first defense against liability issues. You need a complete record-keeping system that has:

- Water Back Flow Preventor Testing and Repair Records

- Original installation documentation

- Annual inspection reports

- Repair history

- Certification of inspection personnel

2. Regulatory Compliance

- Local authority approvals

- State-specific certifications

- Testing frequency documentation

- Remedial repair options

Whatever your property, residential or commercial type, you must keep these records for at least three years. Even routine maintenance might not shield you from liability claims without proper documentation.

Rules change by jurisdiction, with specific needs based on your property type and usage. Healthcare facilities face tougher regulations due to their high-risk status. Property owners must ensure:

- Regular testing by certified professionals

- Proper installation according to local codes

- Maintenance of all required permits

- Compliance with state-specific regulations

Many jurisdictions ask for yearly testing of backflow prevention devices. If you don't follow these requirements, you might face:

Consequence Impact

· Financial Penalties Fines and increased insurance premiums

· Legal Actions Court proceedings and liability claims

Service Interruption Water Service Disconnection

Property Access Restricted facility operations

Local water suppliers must maintain water purity standards according to the Environmental Protection Agency (EPA). These suppliers need property owners to:

- Get proper permits for installation and modifications

- Schedule annual inspections with certified professionals

- Maintain accurate testing records

- Report any incidents promptly

Commercial Properties Face Extra Water Backflow Prevention Device Requirements

- Higher insurance coverage requirements

- More frequent testing schedules

- Stricter documentation standards

- Enhanced monitoring requirements

Good insurance coverage and documentation protect you against potential claims. Smart investments include proper backflow prevention devices and appropriate insurance coverage.

Note that standard policies often don't cover water damage incidents. We strongly suggest you:

- Review your current insurance policy

- Add specific water backup endorsements

- Maintain detailed maintenance records

- Keep all certification documents current

These requirements might look complex, but the potential risks of non-compliance make proper attention vital. Working with certified professionals ensures you handle and document all compliance aspects correctly.

THE FUTURE OF BACKFLOW PREVENTION: SMART & IOT SYSTEMS

New smart backflow systems use sensors and remote monitoring to detect pressure changes, leaks, and failures in real time. These systems are increasingly used in large commercial and multi-property facilities to improve compliance and reduce downtime.

While traditional mechanical systems remain standard, smart monitoring is becoming a valuable upgrade for property managers.

Water backflow prevention is a vital safeguard for our homes and businesses. Our largest longitudinal study shows how these devices protect drinking water from contamination and meet legal requirements. Smart technology makes monitoring and maintenance easier than ever. Device selection and professional installation still remain critical factors.

Emergency response protocols are a great way to get protection when problems occur. Regular testing, proper documentation, and adequate insurance coverage protect property owners from potential risks. These protective measures often get overlooked but become essential during contamination risks or legal challenges.

Backflow prevention might look complex at first glance. Understanding its importance helps protect public health and your property's value.

Professional guidance will give a system that meets requirements and works properly. You can learn more about selecting and maintaining the right backflow prevention solution that fits your needs. Note that protecting your water supply goes beyond mere compliance. Clean water ensures the health and safety of everyone who relies on it. Smart choices about backflow prevention today help avoid problems that can get pricey tomorrow. Call Drain Brain LLC at 720-322-4845

Frequently Asked Questions About Backflow Preventers in Denver

What is a backflow preventer and why do I need one in Denver?

A backflow preventer is a required plumbing safety device that stops contaminated water from flowing backward into Denver’s public drinking water system. Denver Water mandates backflow prevention for many homes and businesses because pressure changes — such as main breaks or high demand — can pull unsafe water into clean supply lines. Without one, your property could pose a health risk and violate local compliance rules.

Is a backflow preventer required for residential homes in Denver?

Yes, many Denver homes are required to have backflow prevention devices, especially properties with:

Irrigation or sprinkler systems

Fire suppression systems

Boilers or auxiliary water systems

Certain plumbing configurations

Denver Water determines requirements based on risk level. Even residential systems may require annual backflow testing if a device is installed.

How often does backflow testing need to be done in Denver?

Most backflow preventers in Denver must be tested annually by a certified backflow tester. Test results must be submitted directly to Denver Water to maintain compliance. Missing or failing a test can result in violation notices or water service interruption.

Who is allowed to perform backflow testing in Denver?

Only a licensed and certified backflow tester approved by Denver Water can perform official inspections. DIY testing or unlicensed inspections are not accepted and will not satisfy compliance requirements.

How much does backflow testing cost in Denver?

Backflow testing costs in Denver typically vary based on:

Device type (RPZ, DCVA, PVB, AVB)

Device size

Accessibility

Residential vs commercial systems

While prices vary, professional testing is

What happens if my backflow preventer fails inspection?

If your backflow device fails:

Repairs or replacement must be completed by a certified professional

The system must be re-tested

Passing results must be resubmitted to Denver Water

Until compliance is restored, Denver Water may issue notices or restrict service.

What type of backflow preventer does my property need?

The required device depends on the hazard level of your water system:

RPZ assemblies for high-risk commercial or industrial systems

DCVA devices for fire sprinkler systems

PVB or AVB devices for irrigation and landscaping

Installing the wrong device can cause failed inspections and code violations, which is why professional evaluation is essential.

Where is a backflow preventer usually installed?

Backflow preventers are commonly installed:

Near the water meter

On irrigation supply lines

On fire sprinkler system feeds

Inside mechanical rooms or outdoors (with freeze protection)

Denver winters make proper placement and insulation especially important to prevent freezing and damage.

Can backflow preventers freeze in Denver winters?

es. Outdoor backflow devices are highly vulnerable to freezing temperatures. Proper installation includes:

Insulation

Freeze-resistant placement

Seasonal winterization when required

Freeze damage is one of the most common causes of backflow device failure in Denver.

Do I need a backflow preventer for my irrigation system?

Yes. Irrigation systems are one of the most common sources of backflow contamination due to fertilizers, pesticides, and stagnant water. Denver Water typically requires PVB, AVB, or RPZ devices depending on system design and risk level.

What is cross-connection control and how does it relate to backflow?

Cross-connection control is the prevention of unsafe connections between potable (drinking) water and non-potable sources. Backflow preventers are the primary method used to control cross-connections and protect Denver’s water supply from contamination.

Can I install or repair a backflow preventer myself?

No. Denver Water requires professional installation, testing, and certification. Improper installation can lead to immediate failure, code violations, and costly corrections.

Why should I hire a professional backflow service instead of a general plumber?

Certified backflow professionals:

Understand Denver Water compliance rules

Install the correct device for your system

Perform official testing and certification

Submit documentation properly

Prevent costly re-inspections and violations

General plumbing work alone does not guarantee compliance.